WP1 – Glasses, and composites for HEALTH care industries

Lead Beneficiary: ERLANGEN

Duration: 6M – 48M

|

Objectives: |

Development of novel glass and composite antibacterial coatings. Development of innovative glass based fibres for biomedical applications |

Outcomes: |

At least 2 prototypes of novel antibacterial coatings produced with different techniques for a short-term market uptake New glass processing technique to produce new optical core- bioactive clad fibres with improved spectroscopic properties to be used as sensors |

Task 1.1 |

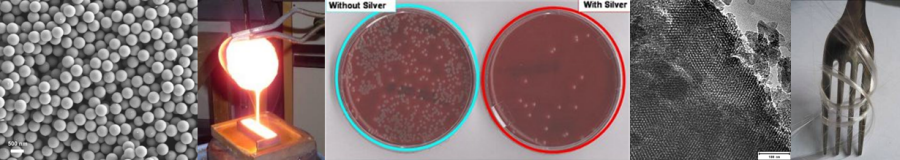

Design, processing and characterisation of innovative coatings with anti-septic properties (ERLANGEN, POLITO, ELEMENT, COLOR, NANOFORCE, BACTIGUARD) The aim of this task is the assessment and development antibacterial coatings with improved adhesion and durability |

|

New strategies to improve adhesion and durability of coatings (COLOR, POLITO, ERLANGEN, BACTIGUARD, ELEMENT): surface modification of the substrates and of the coating compositions (POLITO, COLOR); deposition of the coatings (electrophoretic deposition, RF-sputtering, sol-gel, …) on different substrates and anti-bacterial tests (ERLANGEN, POLITO, BACTIGUARD); durability and wear resistance tests (COLOR, ELEMENT) |

|

Mesoporous glasses and nanofibres based coatings for controlled drug realease (ERLANGEN, COLOR, NANOFORCE, POLITO, ELEMENT): development of new mesoporous glasses with antibacterial effect (ERLANGEN, NANOFORCE); nanofibres with nano reservoirs (NANOFORCE, ERLANGEN, POLITO); deposition of the coatings on different substrates and anti-bacterial tests (ERLANGEN, NANOFORCE, POLITO, COLOR); durability and wear resistance tests (COLOR, ELEMENT) |

Task 1.2 |

Design, synthesis and characterisation innovative glass based fibres for biomedical applications (nLIGHT, POLITO, UR1, DIAFIR, COLOR) The aim of this task is to produce innovative doped glasses and glass fibres for fibre amplifiers and fibre laser for medical diagnostics and therapeutics in healthcare applications |

|

Development of an unconventional new glass process: chemical synthesis of new rare-earth containing nanoparticles (POLITO, COLOR); dispersion of the nanoparticles in silica based glasses (POLITO, COLOR); characterisation of physical, thermal, optical and structural properties (POLITO, nLIGHT, UR1, DIAFIR) |

|

Design and production of the fibre optic displacement sensor (nLIGHT, POLITO, UR1, DIAFIR) |

WP2 – Glasses, glass-ceramics and composites for the ENERGY production and ICT industries

Lead Beneficiary: ELEMENT

Duration: 6M – 48M

|

Objectives: |

Development of innovative low cost glass based sensors and new test and modelling methods for advanced composites in harsh environments Development of novel glasses, ceramics and composites for energy harvesting/scavenging Development of new synthesis routes for the densification of nanostructured thermoelectric materials and techniques to fabricate thermoelectric devices Development of novel glasses, ceramics and coatings for solid oxide electrolysis cell (SOEC) |

Outcomes: |

Full-scale prototype of a smart GRP with new and cost-effective glass based chemical sensors embedded New test and modelling methods for long term degradation of GRPs in petrochemical applications At least two new thermoelectric materials with ZT> 1.5 and a thermoelectric device operating at T up to 500°C New SPS die designs to enable densification of nanostructured thermoelectrics and encapsulation materials SOEC short stack (at least 5 cells) with improved performance and durability in comparison with the SoA |

Task 2.1 |

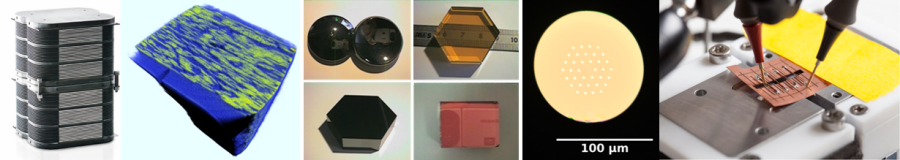

Design, manufacture, integration and testing of innovative glass fibre based sensors for detecting ingress of chemicals in glass fibre reinforced composites in harsh environments (ELEMENT, POLITO, UR1, IPM, NANOFORCE, nLIGHT) The aim of this task is develop new low cost chemical sensors to be embedded in advanced composites in order to monitor the diffusion of corrosive media and degradation through the thickness of the protective liner of a petrochemical component, thus assisting with the development of a more reliable accelerated ageing test to assess the performance of composites in hostile environments |

|

Development of sensors: design of the optical fibre sensors (OFS) for chemicals in harsh environments (POLITO, ELEMENT); fabrication and characterisation of specialty glass fibres (POLITO, nLIGHT, IPM); development of the innovative sensor device (POLITO, UR1); integration and testing of the sensing inside the GRP (POLITO, ELEMENT, NANOFORCE) |

|

Development of test and modelling methods for long term degradation of GRP: accelerated ageing tests of GRP with sensors embedded (ELEMENT); diffusion & ageing measurements (POLITO, ELEMENT); model development (ELEMENT, IPM) |

Task 2.2 |

Design, processing and characterisation of novel glasses and new silicide and sulphide materials for energy harvesting/scavenging (NANOFORCE, POLITO, UR1, ETL, DIAFIR). The aim of this task is produce new thermoelectric materials and devices with high efficiency in a broad range of temperatures. |

|

Development of new, inexpensive, and highly efficient thermoelectrics: processing of novel telluride glass based materials by low-cost processes (UR1) and development of non-toxic, nanostructured thermoelectrics based on silicides and sulphides (NANOFORCE); characterisation of the new thermoelectrics (UR1, NANOFORCE, ETL, DIAFIR) |

|

Fabrication of thermoelectric devices: developing of new joining technologies in order to mitigate thermo-mechanical mismatches between the components and to increase thermal shock resistance (ETL, POLITO); devices fabrication & testing (ETL) |

Task 2.3 |

Design, synthesis and characterisation of glasses, glass-ceramics and ceramics for solid oxide electrolysis cell technologies (SUNFIRE, POLITO, ERLANGEN, IPM, NANOFORCE) The aim of this task is the development of innovative spinel protective layers for interconnects to improve the corrosion resistance of the interconnect in dry oxygen and to design and produce glass-based sealants to guarantee gas tightness in devices, thus allowing the fabrication of more efficient and durable SOEC devices |

|

Design, manufacturing and testing of innovative protective spinel coatings: coating design (SUNFIRE, POLITO); deposition of spinel coatings by RF-sputtering (POLITO) and electrophoretic deposition (ERLANGEN), and electrophoretic deposition (ERLANGEN); characterisation of key components in SOEC relevant conditions |

|

Design, manufacturing and testing of new sealants: design of new glass based sealants (including a rigid-compliant multilayer composite approach) (POLITO, SUNFIRE); optimisation of the joining process (POLITO, NANOFORCE); short stacks fabrication & testing (SUNFIRE, POLITO, ERLANGEN, NANOFORCE); development of new mechanical integrity tests (IPM) |

WP3 – ENVIRONMENT-friendly, low cost glass, ceramic and composite materials

Lead Beneficiary: UNIPD

Duration: 6M – 48M

|

Objectives: |

Development of low-cost glass-ceramic proppants from waste for the oil and gas industry Development of low cost eco-friendly insulation materials and geopolymers based materials incorporating industrial wastes |

Outcomes: |

Glass-ceramic proppants with lower cost and properties comparable with the current commercial ones Prototypes of thermal and acoustic insulation panels from industrial wastes |

Task 3.1 |

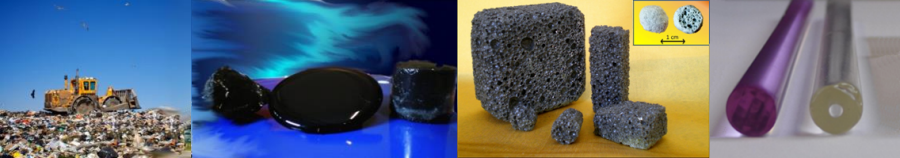

Development and characterisation of glass-ceramic proppants for the oil and gas industry (UNIPD, POLITO, ERLANGEN, IPM, ELEMENT, SASIL). The aim of this research topic is the design and manufacture of glass-based materials to be applied as as proppants (SASIL, UNIPD) |

|

Design and sintering of glass-ceramic proppants: design of suitable glass compositions by selection and combination of industrial waste (metallurgical slags, fly and bottom ashes from incinerators and power plants, mine tailings etc.) (SASIL, UNIPD); melting of waste derived glasses with the preparation of glass frits, the fabrication of sinter-crystallized beads (with optimized binders) (UNIPD, SASIL) |

|

Characterisation of glass-ceramic proppants: mechanical and chemical properties (strength, hardness, fracture toughness (POLITO, ERLANGEN, IPM), and resistance to acid solutions pumped into wells to clear blockages (ELEMENT) |

Task 3.2 |

Low cost glasses, ceramics and composite materials from waste: new eco-friendly insulation materials and geopolymers based materials (ERLANGEN, POLITO, UNIPD, IPM, SASIL) The ultimate aim is to assess the possibility of using geopolymers containing silicate from waste to develop thermal and acoustic insulation panels |

|

Mix design and production of the insulation materials: characterization of industrial waste and selection of suitable mixtures (UNIPD, ERLANGEN), fabrication of foamed granules and/or panels at lab scale (direct foaming of glass foam panels, binding of glass foam granules with geopolymers, direct obtainment of geopolymer foams) (UNIPD, ERLANGEN) |

|

Characterisation of the insulation materials and full-scale prototype: characterization in terms of microstructure, mechanical (IPM) and chemical properties (strength and stabilization of pollutant possibly present in the raw materials) (UNIPD, POLITO). Production of prototype panels (SASIL) |